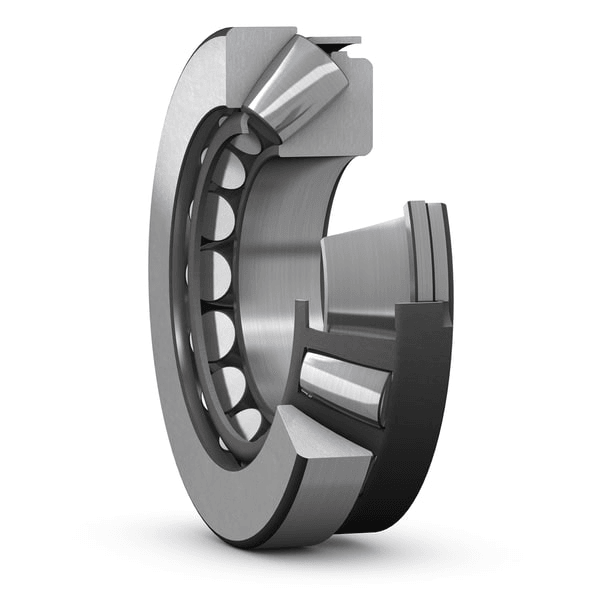

Spherical roller thrust bearings have specially designed raceways and asymmetric rollers. Bearings can withstand axial loads acting in one direction and radial loads acting simultaneously. The load is transmitted between the raceways through rollers at a certain angle to the bearing axis, while the retaining edge guides the rollers.

High load-bearing capacity

A large number of rollers with optimal consistency with the shaft raceway help the bearing withstand heavy axial and radial loads.

Allow for misalignment

Spherical roller thrust bearings are self-aligning and can withstand misalignment.

Separate design

The thrust spherical roller bearing is a separable type, allowing its seat ring to be installed and removed independently of the shaft washer, roller, and cage components. In addition, this is beneficial for maintenance inspections.

High speed capability

The optimal consistency between the cage design and the roller and washer raceway makes the bearing suitable for relatively high speeds.

long service life

The special roller shape reduces the edge stress at the contact between the roller and the raceway.

Low Friction

The optimized roller end/edge contact can maintain the heat generated by friction at a low level even at high speeds.