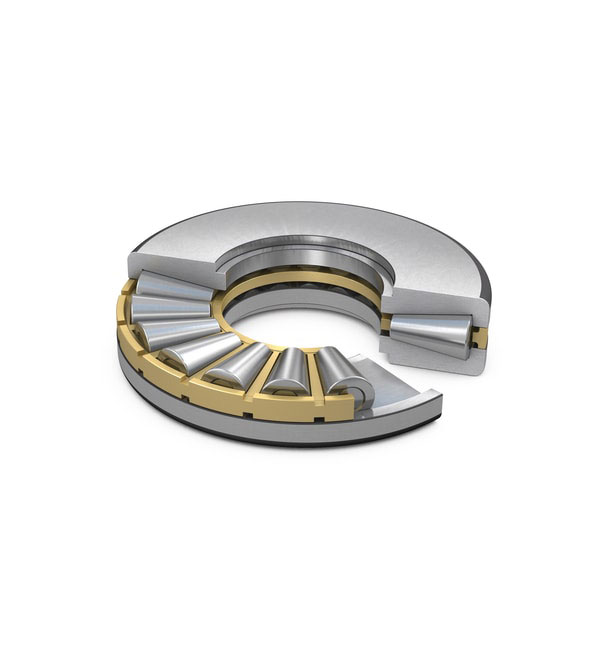

Conical roller thrust bearings can withstand heavy axial loads and peak loads. The bearing has high stiffness and only requires a small axial space.

Separate design

The shaft and bearing seat washers of the tapered roller thrust bearing with a cage, as well as the roller and cage thrust components, can be installed separately.

Low Friction

The optimized roller design on the edge and the smoothness of the edge surface can promote the formation of a lubricant film, thereby reducing friction. This also reduces the heat generated by friction and edge wear.

long service life

Depending on the design, compared to conventional designed raceways, the convexity or logarithmic raceway shape can optimize the load distribution along the contact surface, reduce stress peaks at the roller ends, and decrease sensitivity to misalignment.

Improve operational reliability

The surface treatment of the contact surface between the roller and the raceway is beneficial for the formation of a hydrodynamic lubricating oil film.

High load-bearing capacity

The manufacturing tolerances and dimensional accuracy of the rollers in tapered roller thrust bearings are extremely precise, to the point where they are almost identical. This provides the optimal load distribution and enables the bearing to withstand heavier axial loads.