About us

Aiming to join hands with global partners and build a rock solid long-term cooperative relationship

Have

+

R&D personnel

Have

+

Production line

Cover an area of

+

Square meter

Have

+

R&D personnel

Have

+

Production line

Cover an area of

+

Square meter

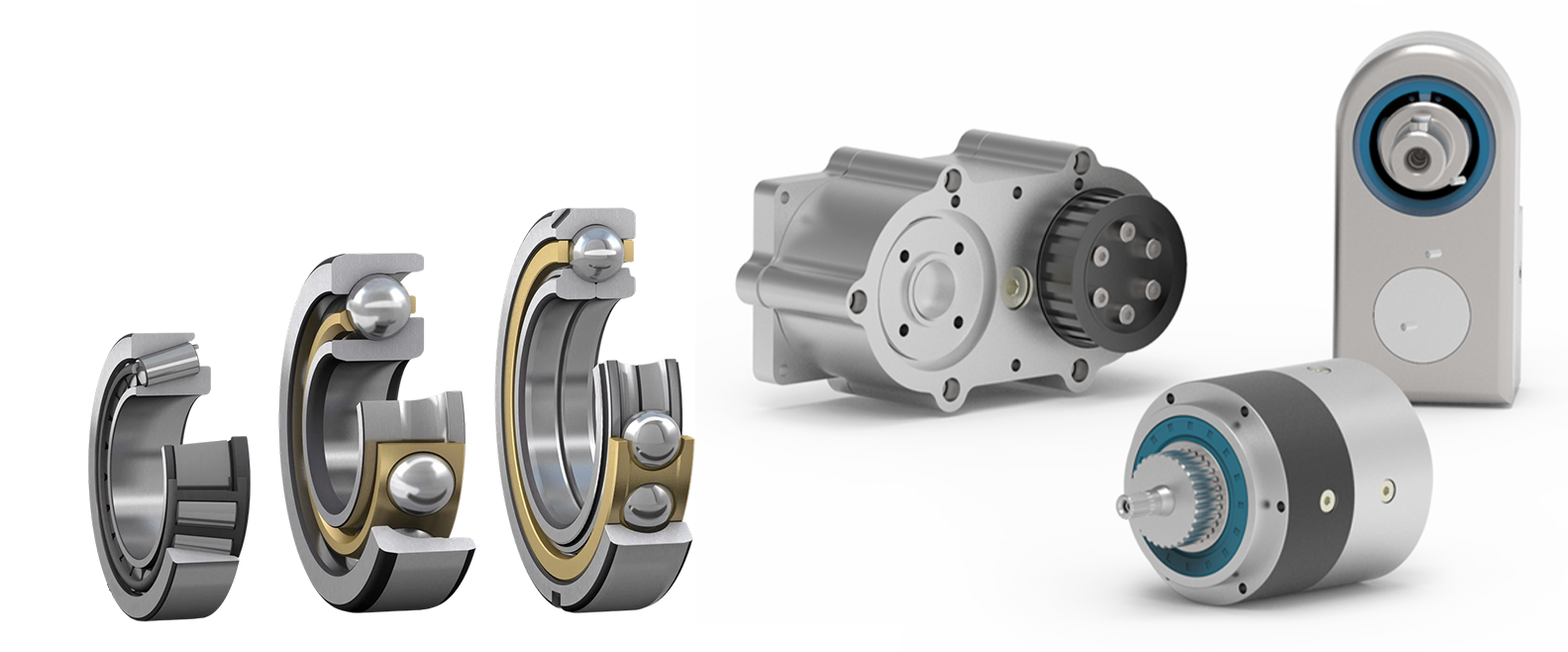

Deeply cultivating the field of bearings, with environmental protection as the concept and efficiency as the goal,

continuously researching and developing innovative products and technologies,

Dare to break conventions, constantly explore in technology and application fields, overcome global industry challenges, and demonstrate hardcore strength.

•••

AKMI dealers can provide you with technical support and sales assistance.

Explore more45+

Country and Region

8000Ten thousand

Annual output value

Regarding the explanation of bearing solutions, if there are more specific issues or a need for more in-depth solutions,

Suggest directlyContact UsSeeking Consultation。

From the initial concept of product development, to professional consultation before sales, efficient coordination during sales, and thoughtful after-sales support, we integrate customer needs into every aspect.

Adhering to the principle of "customer first", with excellent quality as the foundation and high-quality service as the link, we continuously improve and innovate to provide customers with a worry free experience throughout the entire process.

Do as you please, satisfy everything

Nationwide, worry free service

Transportation is controllable and the product is undamaged

Ultra long warranty, worry free quality

Efficient, convenient, and unobstructed

Generally speaking, rolling bearings with tight fi...

Learn moreIn order to avoid contaminants including moisture,...

Learn moreWhether the correct installation of bearings, rela...

Learn moreSliding bearing is a kind of sliding friction natu...

Learn moreCan't find the information you're looking for? Please fill out the application form and we will reply to you as soon as possible.

Your local AKMI dealer can provide you with technical support and sales assistance.

AKMI online customer service, timely answer customer questions

(Monday to Friday 9:00-18:00)